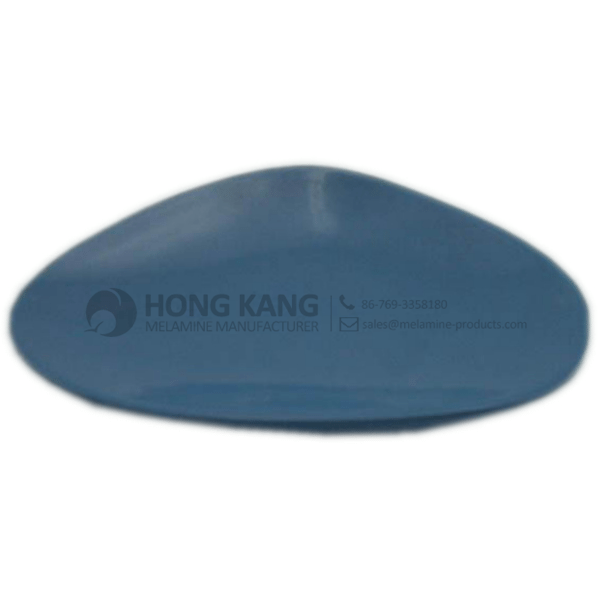

15 Years Factory wholesale melamine dessert plate for Pakistan Factories

15 Years Factory wholesale melamine dessert plate for Pakistan Factories Detail:

| Specification | |

| Item Name | 9inch Round Melamine Dinner Plate |

| Item No. | PT201 |

| Shape | Round |

| Body Color | White |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 6pcs/box,24pcs/carton |

| Dimensions | |

| Length | 22.7 cm |

| Width | 22.7 cm |

| Height | 1.7 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No, |

| Weights | |

| Net Weight (kg) | 7.8 |

| Shipping Weight (kg) | 9 |

Product detail pictures:

Related Product Guide:

Top Ten Power Toothbrushes

Affordable Types of Dinnerware Sets

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for 15 Years Factory wholesale melamine dessert plate for Pakistan Factories, The product will supply to all over the world, such as: Sri Lanka , Burundi , Oslo , We've got sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.