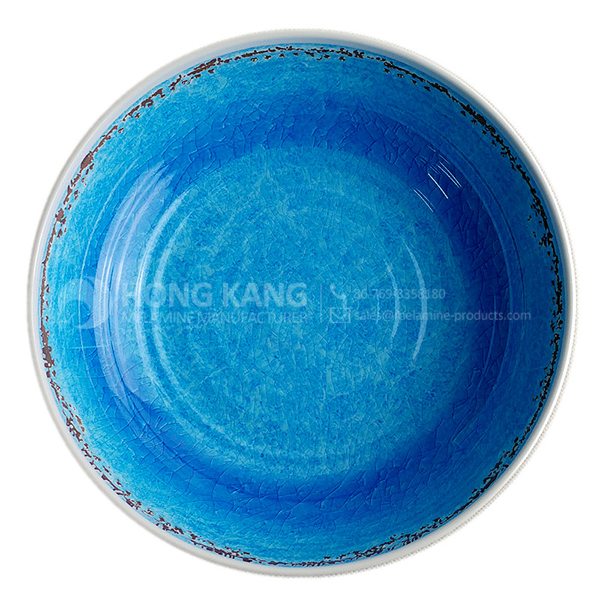

Customized Supplier for melamine mixing bowls for Myanmar Importers

Customized Supplier for melamine mixing bowls for Myanmar Importers Detail:

| Specification | |

| Item Name | 5pcs Round Melamine Mixing Bowl Set |

| Item No. | BW025 |

| Shape | Round |

| Body Color | Colorful |

| Decal Color | 4 colors print (if need) |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 1set/box,2set/carton |

| Dimensions | |

| Length | 30.2*30.2 cm/ 26.5*26.5cm / 22.7*22.7 cm/ 19.6*19.6 cm /16*16 cm |

| Width | 30.2*30.2 cm/ 26.5*26.5cm / 22.7*22.7 cm/ 19.6*19.6 cm /16*16 cm |

| Height | 12.6cm / 11.2 cm / 9.6 cm / 8.3 cm / 7 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 3.3 |

| Shipping Weight (kg) | 4.8 |

Product detail pictures:

Related Product Guide:

The Benefits Of Using Silicone Kitchen Utensils

Top Ten Power Toothbrushes

"Based on domestic market and expand overseas business" is our development strategy for Customized Supplier for melamine mixing bowls for Myanmar Importers, The product will supply to all over the world, such as: Kazakhstan , Adelaide , Somalia , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

I started with a cardboard box an AC filter and a 20×20 fan. This is the next step. I took my cues from pictures posted by JacKhoLe on customfighters.com. You will see images he posted at the end of the video. It took about 2.5 sheets of Melamine and about 6 2×6′s to build this. If you do an image search for DIY Powder Coat Booth his pictures will come up. I’m very happy with the result.

Jane Zhang

Mobile/whatsapp/viber: 0086 13792591758

Email: janeyuxiao@hotmail.com

Skype: janebelieve

Wechat/QQ: 158265953

PS foam box forming machine

PS foam box forming machine

PS foam box forming machine

PS foam box forming machine

Disposable PS foam food box production line

EPS plate forming and cutting machine manufacturer

Polystyrene Plate Machine Line

PS lunch box foaming machine

ps disposable lunch box machine,ps foam plastic one-off lunch box forming machine,ps foam disposable fast food box making machine

Take Away Fast Food Box Making Machine

PS Foam Sheet Extrusion LinePS Foam Sheet Extruder uses a tandem screw

technology to produce fine-blocked cell-structured extruded Polystyrene foam

sheet with high strength and a pearly and even surface, in a continuous roll,

from Polystyrene injecting an eco-friendly blowing gas and additives. It has a

user-friendly operating system with Inverter controlled driving, Digital

Temperature control and Hydraulic screen changer

Applications Of Product

External packing material for food, fruit, cosmetics and internal cushioning.

Packaging for high-grade goods, industrial machinery parts.

Container for pharmaceutical & medical products.

Various types of lunch boxes, trays and containers

Toy and educational materials due to easy-fabrication

Advertising and stationary board etc.

EPS PS foam tray making machine mainly has three main machines:

1. PS foam sheet extruder: make PS foam sheet, capacity is from 50-600kg/h.

2. Fully auto forming and cutting machine: form PS foam rolls to different foam box/container/tray/plate/bowl etc by changing the moulds

3. Plastic recycle machine: recycle waste to granules for making PS foam rolls

A. PS Foam Sheet Extruder

PS Foam Sheet Extruder uses a tandem screw technology to produce fine-block cell-structured extruded polystyrene foam sheet with high strength and a pearl and even surface, in a continuous roll, from polystyrene injection an eco-friendly blowing gas and additives. It has a user friendly operating system with inverter controlled driving, digital temperature control and so on.

B. Fully auto forming and cutting machine

Fully automatic forming and cutting machine integrates forming, cutting and stacking (trimming) at the same time. It has the features of saving labor, improving efficient, lowing labor intensity and reducing production cost. It adopts PLC controller and touch screen to control the working program. Two workers are enough for whole production line.

The machine is plastic sheet forming equipment in one step with following process: transporting sheet, heating, forming, cutting, stacking and winding waste edge.

C.Plastic recycle machine

Plastic recycle and pelletizing machine is designed to reclaim the foamed polystyrene materials almost identically to new ones with its own superior filtering performance.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!