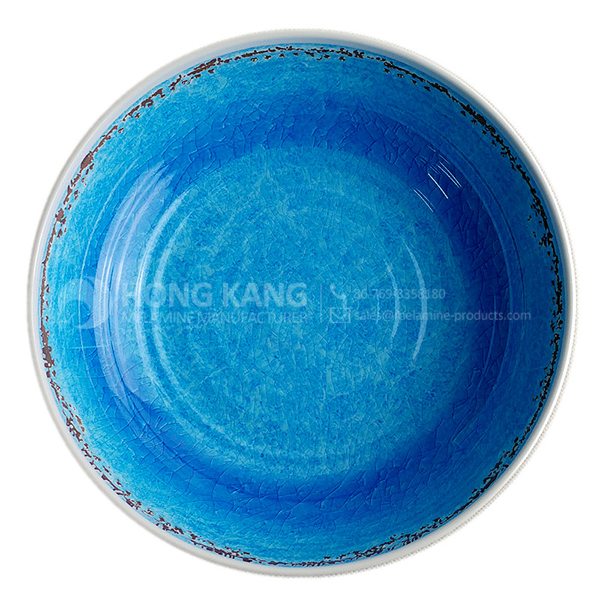

Professional Design melamine cake stand to Dominica Factory

Professional Design melamine cake stand to Dominica Factory Detail:

| Specification | |

| Item Name | 13.75inch Melamine Cake Stand |

| Item No. | TR001 |

| Shape | Round |

| Body Color | Colorful |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 1pcs/box,2pcs/carton |

| Dimensions | |

| Length | 35 cm |

| Width | 35 cm |

| Height | 15 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 1.4 |

| Shipping Weight (kg) | 2.5 |

Product detail pictures:

Related Product Guide:

The Benefits Of Using Silicone Kitchen Utensils

Top Ten Power Toothbrushes

As for aggressive rates, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such good quality at such charges we are the lowest around for Professional Design melamine cake stand to Dominica Factory, The product will supply to all over the world, such as: India , Lyon , Manila , Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

WELCOME TO S.K.INDUSTRIES & S.K.ENGINEERS CALL 24X7 CASTUMER CARE 0808130-8899 089235-42268 093199-33241 9456624895 Low Price Machinery For Sale Thermocol Dona-Plate Machine, Disposable Glass Machines, Paper Dona-Plate Machines, Paper Cup Machines, Food Processing Machines, Plastic Product Making Machine, Textile Machineries, Different Pouch Packaging Machines, Mineral Water, Note Book Making Machine, Melamine Crockery Machine, Interlocking Machine, Candle Machine, Bakery Machines 2000 Machines Etc.…@34,999/Onwards

0% Finance

Free Training/Marketing Agreements & up to 25% off

Apna Full Name-Address, Email.id Sms Kre. NAVED AHMED (MANAGING DIRECTOR)

S. K. INDUSTRIES

102 GARDEN CITY NEAR AKASH TOVER ALMADINA HOSPITEL

OPP HDFC BANK PAWAN VIHAR COLONY GATE ,BISALPUR CHAURAHA,

UNIVERCITY ROAD

BAREILLY (U.P) WEBSIDE LOGIN KAREY www.skengineers.info , www.smallscaleindustries.in email karey skengineersbly@gmail.com CALL NAVED AHMED 08755011715 AYAZ 07037593408 SUMIT 07037593408 MUMTAZ 07037593218 CALL TIME 10 AM TO 6 PM N HOTEL YA TAXE AUTORIKSHA KE ENQUIRE KE LIA HAME BAREILLY ROADWAYS YA RAILWAY STATION SE HAME CALL / SMS / WHATSAPP KAREY MOBILE NO 09412292815 08755011715 08410085551 09319933241

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!