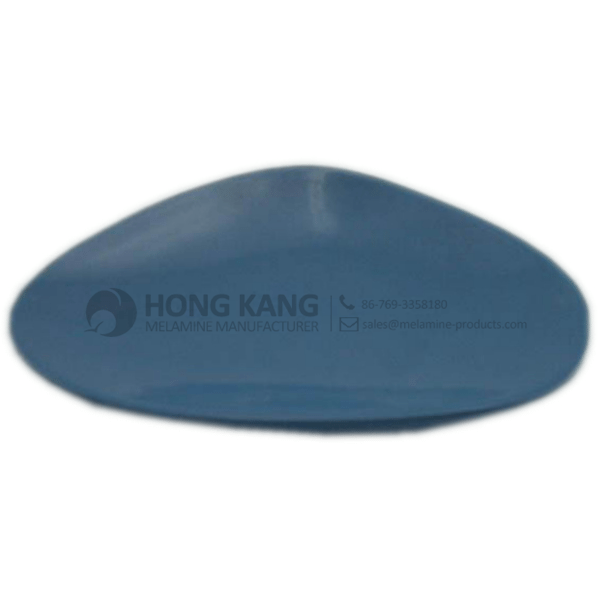

Trending Products 6inch Melamine Sushi Plate for Germany Manufacturer

Trending Products 6inch Melamine Sushi Plate for Germany Manufacturer Detail:

| Specification | |

| Item Name | 6inch Melamine Sushi Plate |

| Item No. | PT007 |

| Shape | Round |

| Body Color | White |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 12pcs/box,72pcs/carton |

| Dimensions | |

| Length | 15.1 cm |

| Width | 15.1 cm |

| Height | 2.1 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 7.6 |

| Shipping Weight (kg) | 8.6 |

Product detail pictures:

Related Product Guide:

The Benefits Of Using Silicone Kitchen Utensils

Top Ten Power Toothbrushes

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Trending Products 6inch Melamine Sushi Plate for Germany Manufacturer, The product will supply to all over the world, such as: Congo , Estonia , Nairobi , Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

Mixed jewelry at clearance prices.

Prices shown on the previously recorded video may not represent the current price. View hsn.com to view the current selling price.SHOP NOW http://www.hsn.com

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!